After much research on how to build an outdoor room, Johan Fröjd chose to make one in log house style.

-“The plans for an outdoor room to sit in the evening sun at the back of the house have been around for a while, I chose to build with logs because it’s a bit of an unusual style,” says Johan with satisfaction.

Johan, who works with repairing forestry machines, runs his own company Fröjds maskinservice. After completing his education at the agricultural high school with a focus on forestry, Johan started working for Ponsse and then became self-employed in 2019.

Johan’s father Sven, who worked as a carpenter, aroused Johan’s interest in wood early on and together they have done many construction projects.

–We recently built the large live-edge tables for the outdoor room together. They are made of solid three-inch elm boards that we bought from a guy in Örebro.

–It’s fun doing woodworking with my dad, and we’re now building another table for the outdoor room.

Large live edge table

Timberframe

-It was a bit to think about as I have not timbered before, to figure out where the weight would be and how I would get the knots together.

The roof is sawn flat to be able to pull the aluminum profiles for the duct plastic.

–It was a fun challenge to get everything straight as the logs are round and tapered.

The floor I made in presure treated wood that I then bent to get the curved shape, I used the same technique as when I built a round starting dock that we have to get started when we go water skiing.

The outdoor room is insulated for spring and fall so when the spring sun is on, the temperature inside quickly goes up over 30 degrees.

–My partner and I are thinking of installing a stove so we can sit here even in winter.

–It’s very nice to be able to see the grain and the twigs in the logs, it gives a living impression, says Johan.

Rounded corners on the deck.

A stove would make the room usable also in the wintertime.

A project to be proud of.

The outdoor room in summertime.

F2+ with ES8 electric saw

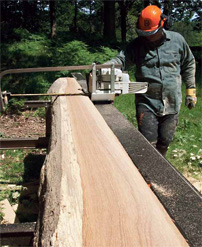

Johan chose to buy an F2+ chain sawmill with ES8 electric saw in 2020 when he and a friend talked about how convenient it would be to have their own saw for construction projects. The saw is on Johan’s father’s property where his father’s carpentry workshop is also located.

–I chose Logosol because I had heard that they work well and have good solutions for sawing, says Johan.

–The best thing about having your own saw is the freedom of being able to cut exactly the dimensions and measurements directly on site. Especially for me, portability is important, I can store the sawmill away in the winter when I’m not sawing and don’t need a saw house, says Johan.

Future projects

With the great result of the outdoor room, the couple have now started sketching ideas for building a greenhouse in a similar style.

-My partner Sofia would love to grow vegetables in the greenhouse to get a slightly longer growing season, we are also thinking of making a grass roof on it.

Johan and Sofia’s journey from idea to finished conservatory is a shining example of what passion for craftsmanship and a sawmill on the farm can achieve! We look forward to following the next project, and the one after that. After all, a sawmill on the farm rarely stands unused!

We hope to inspire others to also explore what is possible with a little creativity and a lot of hard work.

The F2+ takes the F2 to the next level! This sawmill is sturdier, heavier, and designed for customers who need an extra-robust machine for handling large logs. All key components are reinforced to withstand the stress of heavy timber, and to accommodate larger logs, the log beds have been extended by a full 20 cm.