Eight Laks saws turned a wrecked pine plantation into profitable forestry with record-low investment costs. The alternative would have been to burn down the whole forest plantation.

Today, huge amounts of money are invested in wood plantations all over the world. The aim is primarily to plant trees and recreate the lungs of the Earth in order to bind carbon dioxide. But only too often the future of the projects is forgotten. How should the woods be taken care of, how are the efforts to be financed, and in what way will all these trees be used in the future? In Tanzania the solution was eight Laks Sawmills.

No stop in production

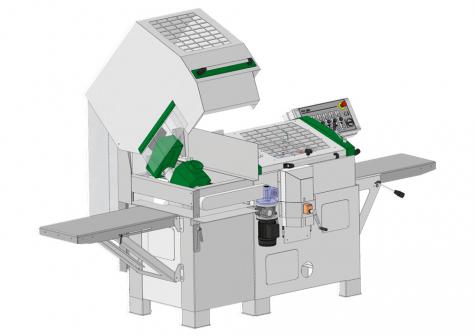

The frame sawmill Logosol-Laks is a simple and stable construction with high capacity and high accuracy, and it leaves a very clean cut. The frame saws were placed side by side with a roller-track system.

The advantage with this was that the logs could easily be moved between the different saw units, and that a fault in one machine did not stop the entire production.

“The plan was that one frame saw would always be shut down for servicing, and this way maintenance could be carried out without disturbing the production,” says Klas Bengtsson, who runs two projects in South America that aim at using forests in a responsible way with the help of small-scale solutions.

The plant was started five years ago and it was immediately a success. The entire investment paid off in eight months, with a yearly production of 1 060 000 cubic feet. The sawmill is still in operation, now with new owners, and the “worthless” pine wood generates export incomes to Tanzania. A plantation that was unsellable a couple of years ago, could in 2007, after very modest investments, be sold for 13 million US dollars. Now SSC Forestry is running a similar project in southern Chile, on a smaller scale for a start. Also this time, the Laks frame sawmill is in the centre of the project.

“We have not found any other solution that has so low investment and operational costs per produced cubic feet,” says Klas.

Amazing result with the Sauno Kiln

The big challenge in Chile is the seasoning of lumber. Different methods have been tried, and the best results have been attained with the Sauno kilns from the Swedish company Plano. These kilns are today also sold by Logosol. The lumber is of beautiful, valuable and hard-to-dry wood types. The drying results are amazing, and now tests are being carried out where biofuels are being used in order to lower the electricity costs. Low costs make it profitable to process even small-diameter logs. This creates a value in woods that earlier were worthless, and it gives the wood owners resources that they can invest in forest regulation. In southern Chile there are many examples of natural forests that have been neglected for centuries. Successively only the most valuable trees have been cut down and the forests have then been left to take care of themselves.